SignTorch

Artist

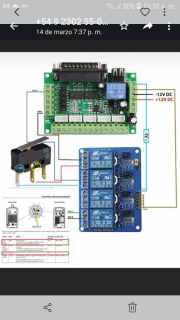

I was working in eagle to re-create the schematic which I can then design a pcb for. I have a question on the TVS-18V 23nF capacitor labeled in your schematic. Is this actually a capacitor or is it a voltage suppression diode?

https://www.electronicsurplus.com/motorola-p6ke18a-diode-tvs-18v

Transient Voltage Suppressor Diode

I found a reciept where I ordered 36V

https://www.mouser.com/ProductDetail/Vishay-Semiconductors/P6KE36CA-E3-54?qs=ACmI7jQvrjou0HXDaeB0pw%3D%3D

I think I made the schematic early on

I think I went with 36V to cover up to 24V supply on the last one I built which is still working

At some point while I was away a tree fell on my home/office and looters took all my stuff so that kinda knocked me out of playing with the electronics