alright - sounds good - I wouldn't expect cedar to cut that much differently - it might help to decrease the bit pass depth to do multiple passes

and I'm assuming v-carve toolpath works here - but it does cut shallower to get through narrows and it does not cut shallower on the mating part so there is a fine line between how much shallower it cuts and how much gap there is before something bottoms out

I think we are ok using v-carve and increasing female total depth of cut to .18 because v-carve should not retract any more than we increased the total depth of cut which is .03 and the top gap is .05 so I think it should not bottom out - theoretically

but I'm only confident about my pocket toolpath calculations where the design is specifically sized for 15 deg v-bit, no flat, .15 max total depth of cut, pocket cut - and changing bottom gap to .02 means changing start depth to .08 and cut depth to .07 to not exceed .15 total depth of cut - and there is < .001 room to spare on width of cut in some places

it does help a lot to scale the design 111% to have > .001 room to spare - especially for v-carving to decrease v-carve retraction if tdoc is .18

my concern is if the bit were to have a flat or small break then that throws everything off a lot, enough to cause a major mismatch between male and female, enough to require recalculating all pocket toolpath depth parameters

I'd inspect the bit with a jeweler's loupe and check the specs because I find it hard to believe it doesn't have a flat or else the tip will break off

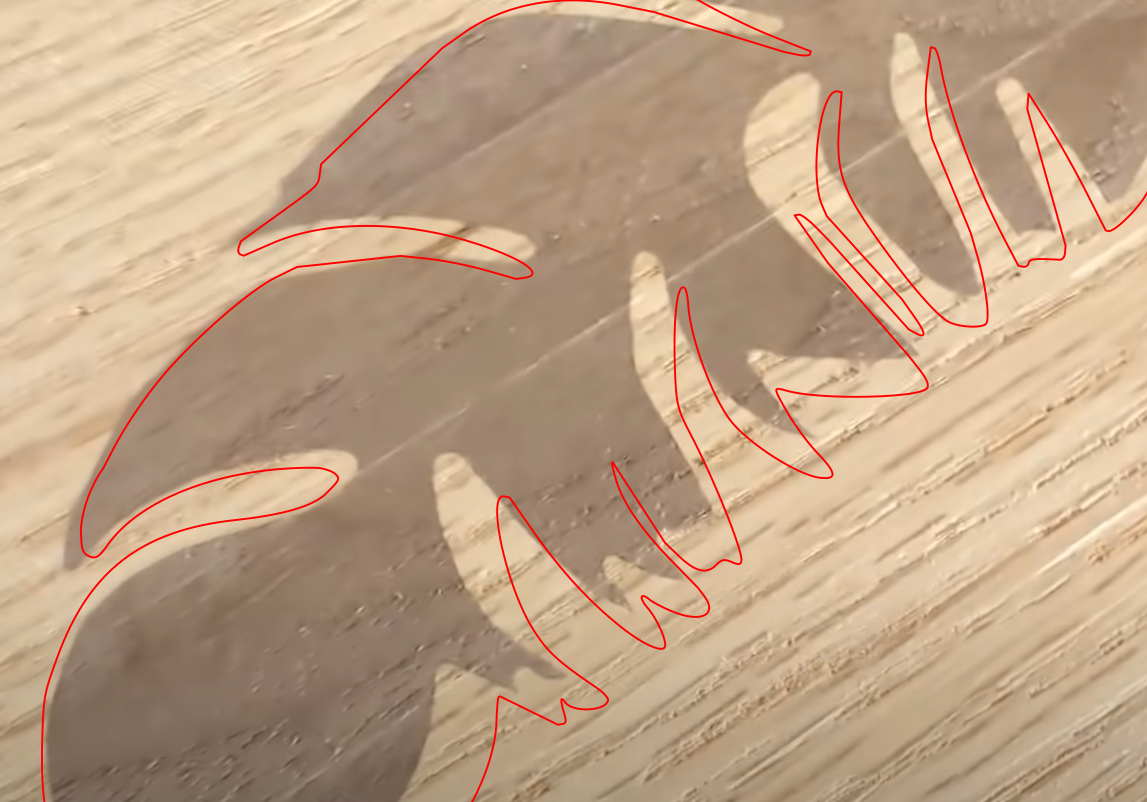

diameter calculations are simple geometry - but the difference between pocket and v-carve, straight and angled bits, clearance and start depth, and how that affects where the toolpath (bit centerline) is relative to the cut path (edge of part) at what depth is convoluted - I don't know of a learning resource to recommend offhand - I like to draw a diagram of the bit to see precisely what depth equals what width - in the diagram below that is a .125 x .15 rectangle and 15 deg bit cutting .03949 diameter at top of rectangle (.15 deep) - and I drew a .005 flat to show how much impact that would have, it would be cutting .04449 diameter at .15 deep and that would not work for this design even at 111% but maybe with v-carving it might work a little better - that's more complex to calculate what happens if the bit and toolpath type is not the same as originally specified