SignTorch

Artist

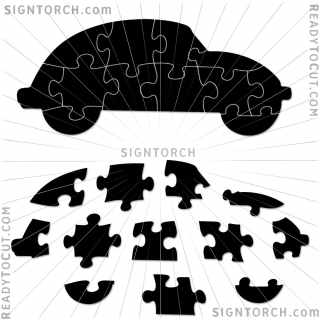

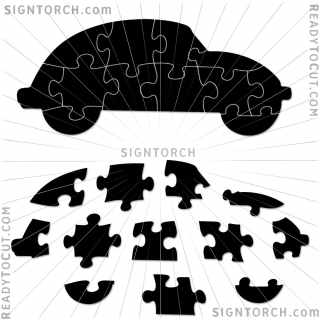

Maximum bit diameter = .125" at size drawn - a larger bit will not fully cut all of the inside curves - which would cause interference between mating pieces

There is no clearance between pieces in the drawing - some clearance must be incorporated in the tool path when cut - how much clearance is required depends on your tooling, material, size, machine characteristics, finish, desired fitment, etc... you can set kerf compensation some amount smaller than your actual kerf and there will be that same amount of clearance between parts

You also cannot use constant velocity because that would round off the sharp corners and cause gaps or interference between mating pieces.

There is no clearance between pieces in the drawing - some clearance must be incorporated in the tool path when cut - how much clearance is required depends on your tooling, material, size, machine characteristics, finish, desired fitment, etc... you can set kerf compensation some amount smaller than your actual kerf and there will be that same amount of clearance between parts

You also cannot use constant velocity because that would round off the sharp corners and cause gaps or interference between mating pieces.

Attachments

You must be signed in to view attachments...

-

vw_puzzle5000.zip88.3 KB