anonymous

incognito

Can someone help with toolpaths for a carve like this?

The customer wants either a 2ftx4ft rectangle or 3ft round circle. It will be double sided. It’s an outdoor sign for a venue. I’m thinking 2” thick Spanish cedar for the wood choice with black painted logo. I want to vcarve it, but just the tree alone is showing an estimated run time of over 20 hours. My current tool is a 30 degree V bit 1/4”. Start depth of .25” with a flat depth of .3”

I’m trying to keep as much detail as possible.

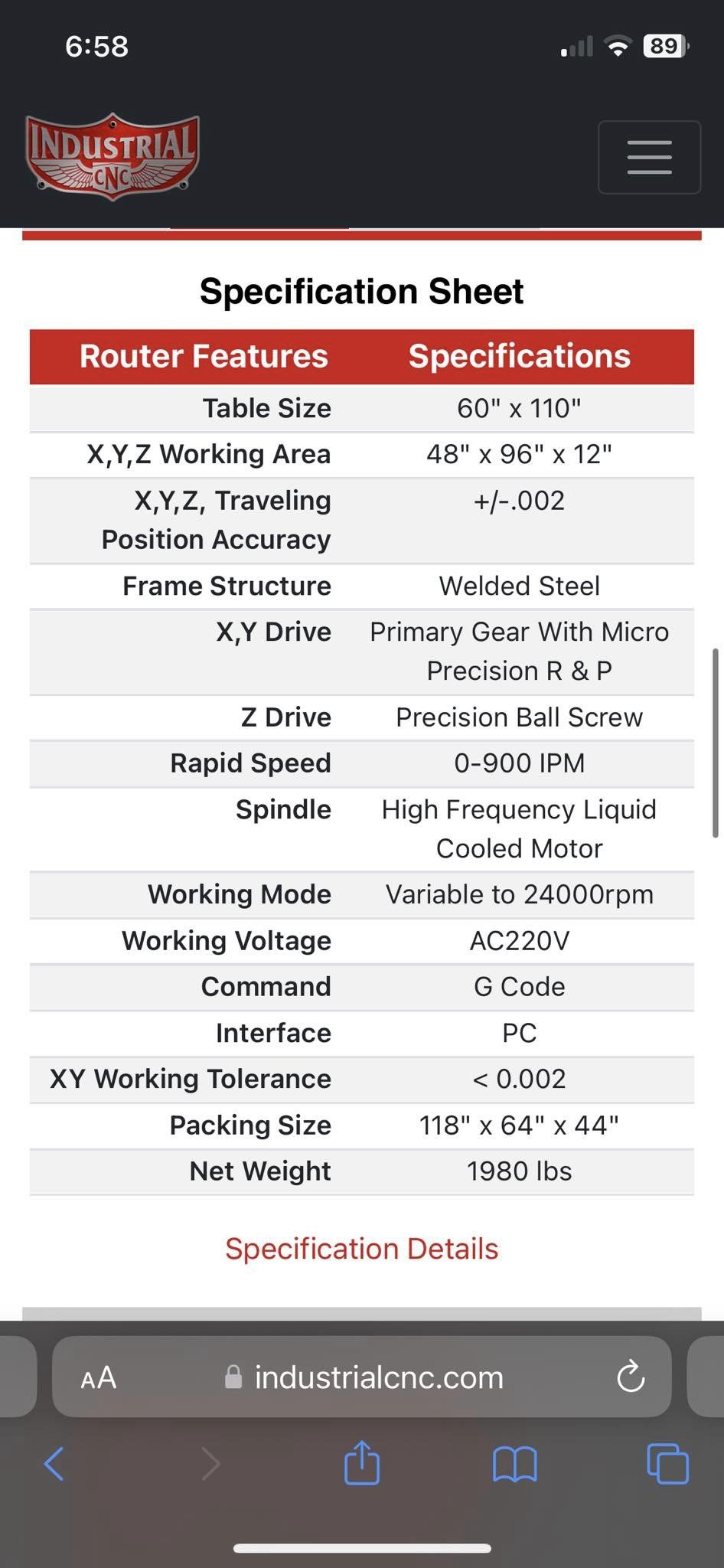

I’m cutting on a 4x8 Artisan Infustrial CNC. I’ve pictured the spec sheet for my machine for any reference if useful to anyone.

I’m still new to this but I’ve carved a few things with quite a bit of detail with way less run times. What am I doing wrong?

Thanks in advance for any tips.

The customer wants either a 2ftx4ft rectangle or 3ft round circle. It will be double sided. It’s an outdoor sign for a venue. I’m thinking 2” thick Spanish cedar for the wood choice with black painted logo. I want to vcarve it, but just the tree alone is showing an estimated run time of over 20 hours. My current tool is a 30 degree V bit 1/4”. Start depth of .25” with a flat depth of .3”

I’m trying to keep as much detail as possible.

I’m cutting on a 4x8 Artisan Infustrial CNC. I’ve pictured the spec sheet for my machine for any reference if useful to anyone.

I’m still new to this but I’ve carved a few things with quite a bit of detail with way less run times. What am I doing wrong?

Thanks in advance for any tips.