SignTorch

Artist

by circle c fab ┬╗ Mon May 21, 2012 9:25 am

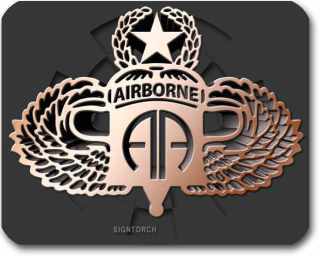

I am doing this as a gift to my brother he retired from the army and he was in the 82nd air born . I am not very good at converting pictures i would appreciate any help thank you so much Scott.

by large_time ┬╗ Tue Apr 16, 2013 8:09 pm

As a Military guy myself, man I am proud of this chunk of stainless.

I am sure that this will be the most prized piece of metal that comes out of my shop for a long long time.

Thanks so much for the share, you made my week brother!

Attachments

You must be signed in to view attachments...

-

jump_master=.zip276.1 KB